Heat Soaked Glass

Heat soaked glass greatly reduces the possibility of unforced breakage and is perfect for applications where additional strength is required.

Glass is formed by combining sand,soda ash,limestone,dolomite,salt cake and various otheringredients into a furnace heated to a temperature around 1500℃. During this process extremely small quantities of nickel sulphide(not visible to the naked eye) can be left undissolved in the glass.

Due to the rapid cooling nature of glass toughening,the nickel sulphide in the glass does not have time to cooldown and is left in its high temperature state whilst increasing in volume .It is this volume increase that causes great stresses in the glass that can cause breakage.

Heat soaking is a precess in which tempered glass is subjected to a temperature of 290℃ for several hours in a heat-soaking oven.This will cause the panel to break if any nickel sulphide inclusions are found.

It is estimated that up to 95% of nickel sulphide-contaminated panes of glass are usually destroyed by this process,reducing the chance of on-site spontaneous breakage.

Heat soaked glass is invaluable for architects and designers,providning added reassurance when specifying projects.

Request a Quote

See the KIAS GLASS processing in Action

High security, high efficiency and a high-tech look with full-vision glass platform for visibility.

Watch Video >>Toughening Laminated Glass Applications

Toughened Glass

Toughened Safety Glass is up to five times stronger than non-toughened and because of its increased strength architects and builders worldwide can take architectural design much further, allowing a lot more natural light into their design whilst maintaining safety.

Learn More >>

Toughened Laminated Glass

Laminated glass, regard as “Safety glass”, consist of two or more panes of glass with one or more layers of polyvinyl butyral (PVB) sandwiched between them and treated.

Learn More >>

Bend Toughened Glass

bend glass is made of flat glass sheets are heated in a special tempering furnace to about 700°C and shaped after exiting the heating zone.

Learn More >>

Heat Soaked Glass

Glass is formed by combining sand, soda ash, limestone, dolomite, salt cake and various other ingredients into a furnace heated to a temperature around 1500°C. During this process extremely small quantities of nickel sulphide (not visible to the naked eye) can be left undissolved in the glass.

Learn More >>

Conservatory Glass

These provide incredible benefits including year-round comfort, self-cleaning properties, reduction in energy bills and beautiful visual options to suit any property style.

Learn More >>

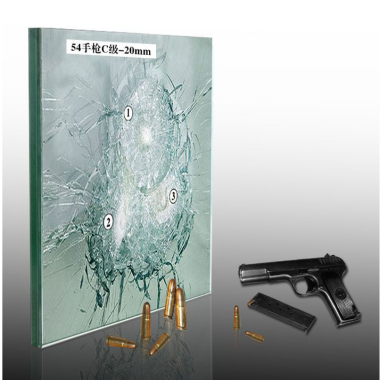

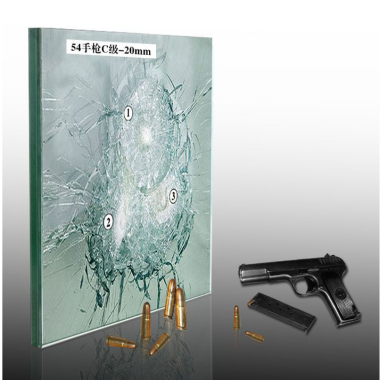

Bullet-proof Glass

bullet-proof glass is made of triple or multiple non-toughened glass combined with pvb,which has feature of light transmission,preventing bullet penetrating glass and glass piece falling down on the ground.Most of bullet-proof glass thickness is 25.52mm(8+8+8mm) and 31.52(10+10+10mm)

Learn More >>